Ratesteel specializes in the production of steel components, delivering installation-ready parts to leading machine manufacturers. Its operations are built on carefully managed processes that enable the company to meet even the most demanding requirements.

According to Sami Hiltunen, who has served as Ratesteel’s factory manager for over a decade, the company has established strong customer relationships over the years, introduced production-enhancing robotics, and developed deep expertise in both automation and production optimization.

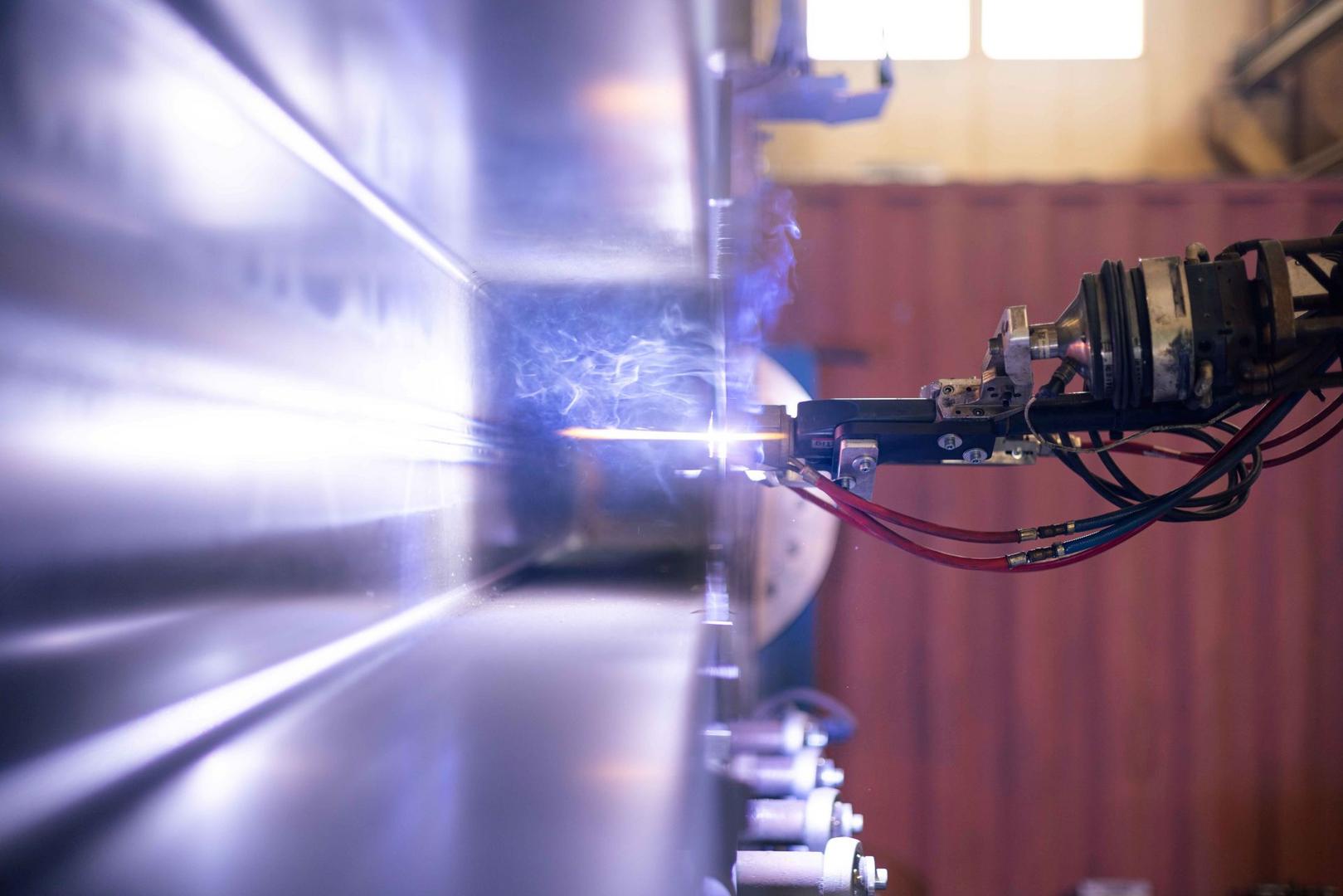

Efficiency Through Robotics and Process Control

Ratesteel’s strengths are especially evident in robotic welding and its efficient management. With nearly 20 years of experience in robotic welding, the company currently operates 15 welding robots, distributed across seven automated FMS production cells – two dedicated to ArcTig welding and five to MAG welding. These optimized methods significantly reduce work phases, the need for manufacturing additional components, and the volume of welding and post-processing.

ArcTig welding is one of Ratesteel’s core areas of expertise, and the company has long been a pioneer of the method in Finland. ArcTig enables considerable cost savings by minimizing work phases, additional components, and the need for welding and post-processing. Alongside ArcTig, Ratesteel utilizes MAG welding, with production environments tailored for fully automated and robotized manufacturing of various product shapes and sizes.

On-Time Deliveries with an Advanced ERP System

Ratesteel’s high delivery reliability is based on the use of advanced quality management tools and regular quality inspections at the factory. The company also applies 3D measurement technology, allowing produced parts to be compared to design models and ensuring full compliance with customer specifications. Analyzing the measurement data allows Ratesteel to detect deviations early and supports proactive quality improvement.

“Thanks to our ERP system, Ratesteel can manage the order-to-delivery chain with exceptional accuracy – we know almost in real time what’s happening on the factory floor. This allows us to meet the demands of our largest customers in terms of both quality and volume,” Hiltunen explains.

Ateno Partnership Strengthens Competitive Edge

In 2022, Ratesteel became a subsidiary of its long-standing partner, Ateno Oy. This strategic partnership has further reinforced Ratesteel’s competitiveness and market position.

“Shared decision-making and a direct logistics link have enabled us to boost our efficiency and strengthen our competitive edge,” Hiltunen concludes.

Read more: Ateno and Ratesteel’s Seamless Collaboration Built on Automated Production and Decades of Expertise